Blockchain technology has revolutionized various industries, and its impact on supply chain management is undeniable. The transparency, security, and decentralization it offers have made it an ideal solution for addressing long-standing inefficiencies in supply chains. However, blockchain alone is not enough to solve every challenge. With the integration of artificial intelligence (AI), particularly in the form of predictive analytics, blockchain-based supply chains are poised for even greater transformation. By combining the strengths of both technologies, organisations can enhance their operational efficiency, reduce risks, and make data-driven decisions with unprecedented accuracy.

Predictive Analytics

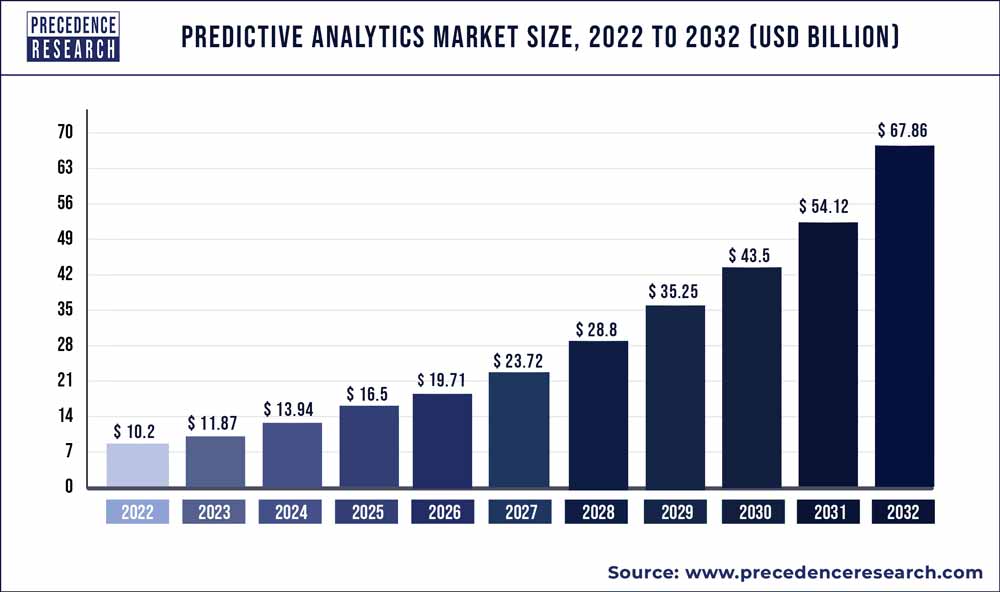

Predictive analytics is the secret sauce that harnesses historical data, statistical algorithms, and machine learning to forecast future events. In a blockchain context, AI dives into the wealth of data recorded in real time, discerning patterns and trends that humans might overlook. This powerful combination enables businesses to anticipate changes, from fluctuating demand to potential disruptions, giving them a significant edge in a competitive landscape. The global predictive analytics market size was valued at USD 10.2 billion in 2022, and it is expected to hit at around USD 67.86 billion by 2032 with a registered compound annual growth rate (CAGR) of 21.4% during the forecast period 2023 to 2032.

Imagine being able to predict shifts in consumer preferences or economic conditions before they impact your operations. With AI’s advanced predictive capabilities, organizations can stay a step ahead, turning uncertainty into opportunity.

AI for Predictive Analytics in Blockchain-based Supply Chains

Predictive analytics has emerged as a game-changer in supply chain management, leveraging historical data to anticipate future trends and outcomes. When this capability is combined with the robust security and transparency of blockchain technology, it creates a potent framework for transforming supply chains into more efficient, reliable ecosystems.

The Role of AI in Predictive Analytics

Artificial Intelligence (AI) is at the forefront of predictive analytics, bringing a suite of capabilities that enhance data utilization:Data Processing and AnalysisAI algorithms excel at sifting through massive datasets from diverse sources—think IoT devices, sensors, and blockchain records. This ability not only accelerates data processing but also uncovers insights that manual analysis might overlook.Pattern RecognitionAI shines in identifying subtle patterns and trends buried in the data. By detecting these hidden signals, AI can help businesses make informed decisions, anticipating shifts in consumer behavior or market dynamics.Predictive ModelingWith AI, businesses can build sophisticated models that forecast future events, using historical data alongside real-time inputs. This predictive power helps organizations stay ahead of the curve in a rapidly changing marketplace.Machine LearningOne of the most compelling aspects of AI is its ability to learn from data continuously. Machine learning techniques enable predictive models to refine their accuracy over time, adapting to new information and evolving circumstances.

Use Cases of Predictive Analytics in Blockchain-based Supply Chains

The synergy of AI and blockchain unlocks various transformative applications:Demand ForecastingBy analyzing historical sales data and market trends, businesses can predict future product demand, helping to align supply with customer needs.Inventory OptimizationAI can optimize inventory levels, preventing stockouts or excess inventory, thus saving costs and improving customer satisfaction.Risk ManagementPredictive analytics helps identify potential risks, such as supply chain disruptions or quality control issues, enabling organizations to implement mitigation strategies before problems arise.Supply Chain OptimizationAI-driven insights can pinpoint inefficiencies and bottlenecks in the supply chain, leading to improved operational performance and cost savings.Quality ControlReal-time data from sensors, coupled with historical insights, allows businesses to predict product quality issues, ensuring standards are met and minimizing waste.

Key Benefits of Integrating AI with Blockchain

Real-time Decision MakingAI excels at processing vast datasets from diverse sources—IoT devices, sensors, and blockchain records—yielding real-time insights. This capability empowers businesses to make swift, informed decisions, enhancing agility in a fast-paced market.Dynamic Supply Chain AdjustmentsPredictive capabilities of AI enable businesses to foresee disruptions and anomalies. For instance, if a natural disaster threatens a supplier, AI can swiftly suggest alternative routes or sources, allowing for seamless adjustments in strategy.Enhanced Transparency and TraceabilityBlockchain’s immutable ledger ensures that all transactions are transparent and traceable. AI can analyze this data to identify inconsistencies or potential issues, reinforcing trust among stakeholders.

Predictive Maintenance in Supply Chains

Predictive maintenance is rapidly becoming a cornerstone of modern supply chain management, enabling businesses to foresee equipment failures before they occur. By integrating AI technologies, organizations can enhance their predictive capabilities, significantly reducing downtime and maximizing operational efficiency.

Advantages of AI-Enhanced Predictive Maintenance

Minimizing DowntimeBy accurately predicting when maintenance is needed, companies can schedule repairs at optimal times, significantly reducing disruptions to operations and ensuring smooth workflows.Boosting Operational EfficiencyPredictive maintenance allows for more efficient maintenance scheduling, reducing waste and enhancing overall equipment utilization. This efficiency translates to better resource management across the supply chain.Cost ReductionsPreventing unexpected equipment failures can save businesses from costly emergency repairs and associated downtime. By investing in predictive maintenance, organizations can reduce overall maintenance costs.Enhancing Product QualityReliable equipment performance directly correlates with product quality. By maintaining equipment in optimal condition, businesses can minimize defects and ensure a consistent product output.Extending Asset LifespanProactively addressing potential issues helps extend the lifespan of equipment. This preventative approach not only saves money but also enhances the overall value of assets.

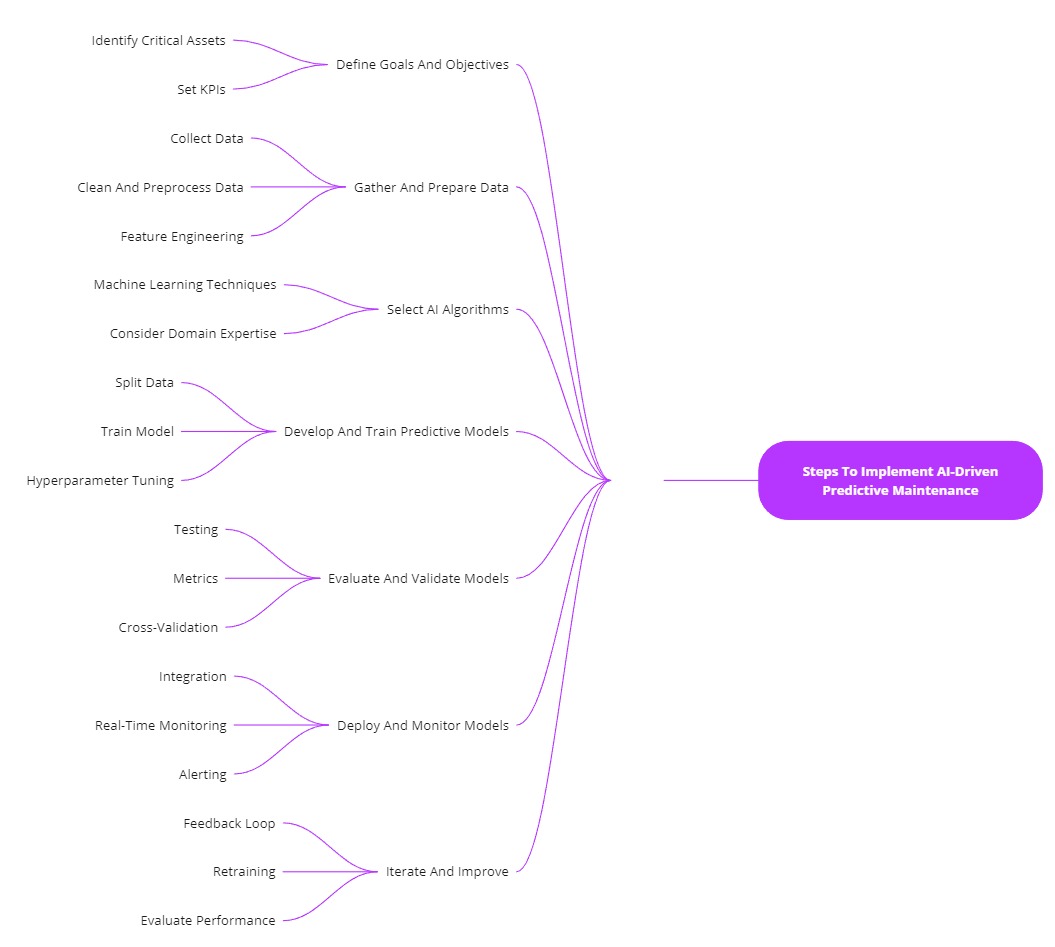

Steps to Implement AI-Driven Predictive Maintenance

Data Collection

Start by gathering relevant data from a variety of sources, including sensors, IoT devices, and historical maintenance records.

Data Preparation

Clean and organize the collected data to ensure its accuracy and consistency, making it suitable for analysis.

Model Development

Utilize suitable algorithms to develop and train machine learning models based on the prepared data.

Model Deployment

Once trained, deploy these models to continuously monitor equipment performance, generating real-time predictions.

Maintenance Planning

Leverage the insights generated by AI to efficiently plan and schedule preventive maintenance tasks, ensuring that operations remain uninterrupted.

Smart Demand Forecasting and Inventory Management

Effective demand forecasting is the backbone of inventory management. AI-driven predictive analytics can sift through historical sales data and external factors, delivering precise forecasts that optimize stock levels. When integrated with blockchain, this information is shared transparently across the supply chain, enabling seamless collaboration between suppliers, manufacturers, and retailers.This synergy not only reduces the risk of stockouts or overstock situations but also fosters a more agile and responsive supply chain ecosystem.

Enhancing Supplier Relationships with Predictive Insights

In today’s competitive landscape, strong supplier relationships are vital for operational success. Artificial Intelligence (AI) is revolutionizing how businesses interact with their suppliers by providing predictive insights that enhance collaboration, performance monitoring, and risk management.

Key Benefits of AI in Supplier Relationships

Predictive Supplier PerformanceAI analyzes historical performance data—like delivery times and quality metrics—to forecast future supplier trends, enabling early identification of potential issues.Comprehensive Risk AssessmentAI assesses supplier risks, such as financial instability and supply chain disruptions, allowing businesses to implement proactive mitigation strategies.Optimized CollaborationReal-time performance insights foster transparency and open dialogue, strengthening partnerships and encouraging joint problem-solving.Smarter Contract NegotiationAI simplifies contract negotiations by analyzing historical data to identify opportunities for better terms, leading to more beneficial agreements.Strategic Supplier SelectionAI helps evaluate suppliers based on performance and risk profiles, ensuring that businesses choose partners aligned with their strategic objectives.

Risk Management Reimagined

Supply chains are fraught with risks, from natural disasters to geopolitical instability. AI acts as a vigilant sentinel, continuously analyzing data to identify potential threats. By integrating real-time insights with blockchain’s secure and transparent records, organizations can formulate effective mitigation strategies. For instance, if weather patterns signal a disruption, AI can suggest alternative routes and adjustments, ensuring that operations remain unaffected.

Real-World Case Studies: AI and Blockchain in Supply Chains

Exploring the integration of AI and blockchain in supply chains reveals transformative applications across various industries. Here are notable examples of how these technologies are optimizing operations:

Maersk’s TradeLens Platform

- Challenge: The shipping industry was hindered by inefficiencies related to document management and lack of transparency.

- Solution: Maersk launched TradeLens, a blockchain platform that digitizes shipping documents and offers real-time supply chain visibility. AI is employed to analyze data and optimize shipping routes, minimizing paperwork.

- Benefits: TradeLens has streamlined shipping processes, improved transparency, and reduced operational costs for both shippers and carriers.

IBM Food Trust

- Challenge: The food sector faced ongoing issues with safety, traceability, and maintaining consumer confidence.

- Solution: IBM Food Trust utilizes blockchain to track food products from the farm to the table, leveraging AI to analyze the data for risks, such as foodborne illnesses.

- Benefits: This platform has bolstered food safety, increased consumer confidence, and expedited product recall processes.

Provenance

- Challenge: The luxury goods market often contends with counterfeit products and a lack of supply chain transparency.

- Solution: Provenance is a blockchain platform that verifies the origin of luxury items. AI is utilized to analyze transaction data to identify and flag counterfeit goods.

- Benefits: This approach has significantly diminished counterfeiting, enhanced transparency throughout the supply chain, and built consumer trust.

Conclusion: A Promising Future Ahead

The fusion of AI and blockchain in supply chain management is not just a trend—it’s a transformative force reshaping the industry. By combining blockchain’s transparency and security with AI’s predictive power, companies are equipped to optimize operations, mitigate risks, and make informed decisions like never before. As these technologies continue to evolve, the future of supply chain management holds immense promise, paving the way for systems that are not only more efficient but also remarkably resilient.

FAQs

What is the difference between generative AI and predictive AI?

Generative AI focuses on creating new content or data by learning patterns from existing datasets. It can produce text, images, music, and more, often simulating human-like creativity. Examples include models like GPT for text and DALL-E for images.Predictive AI, on the other hand, analyzes historical data to forecast future outcomes. It identifies patterns and trends to predict what is likely to happen next, making it useful for applications like demand forecasting and risk assessment

What are the 5 common types of supply chain analytics?

- Descriptive Analytics: Analyzes past data to understand what happened, providing insights into historical performance and identifying trends.

- Diagnostic Analytics: Examines historical data to determine the reasons behind past outcomes, helping to answer the “why” of events.

- Predictive Analytics: Uses statistical models and machine learning to forecast future events based on historical data, commonly applied in demand forecasting and inventory management.

- Prescriptive Analytics: Offers actionable recommendations based on predictive analysis, guiding businesses on the best course of action to optimize outcomes.

- Cognitive Analytics: Combines AI and machine learning to mimic human thought processes, enabling advanced insights and automation in decision-making across complex datasets.

Describe the three core components of supply chain analytics

- Data Collection: Involves gathering data from various sources, such as sensors, enterprise resource planning (ERP) systems, and external market data to build a comprehensive dataset.

- Data Analysis: Applies analytical methods to interpret the collected data, utilizing techniques like statistical analysis, machine learning, and visualization to extract meaningful insights.

- Decision Support: Provides actionable insights and recommendations to stakeholders, empowering them to make informed decisions that enhance supply chain efficiency and effectiveness.

What is the most used technique in predictive analytics?

The most commonly used technique in predictive analytics is regression analysis. This statistical method estimates relationships among variables, enabling organizations to predict outcomes based on historical data trends. It is widely utilized for demand forecasting, sales predictions, and risk assessment.