Integrating Artificial Intelligence (AI) with blockchain technology transforms how predictive maintenance is approached in Internet of Things (IoT) networks. This fusion of technologies offers unprecedented accuracy, efficiency, and security, reshaping industries by enabling more proactive and data-driven maintenance strategies.

In this article, we explore how the integration of AI-powered predictive maintenance with blockchain-based IoT networks is revolutionizing industries by enhancing efficiency, security, and data-driven decision-making.

Blockchain-based IoT Networks

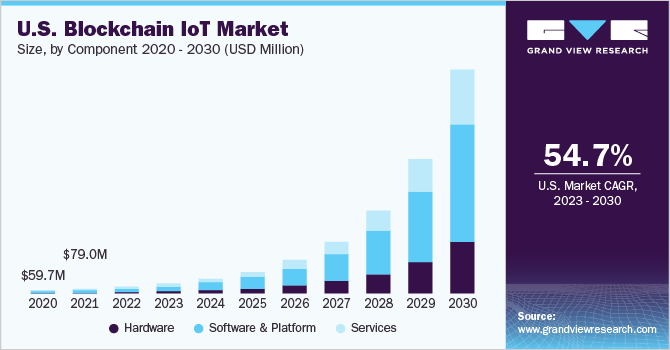

IoT networks consist of interconnected devices that collect, transmit, and act on data. These networks are integral to various applications, from smart homes to industrial automation. Blockchain technology enhances IoT networks by providing a decentralized, immutable ledger for recording transactions and data exchanges.The role of blockchain in IoT is multifaceted. It ensures data integrity by preventing tampering and unauthorized access. Use cases of blockchain in IoT include supply chain tracking, which provides transparency and traceability, and smart contracts, which automate processes based on predefined conditions. The global blockchain IoT market size was estimated at USD 351.9 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 58.2% from 2023 to 2030.

AI-Powered Predictive Maintenance

In today’s dynamic industrial landscape, predictive maintenance has emerged as a game-changer, shifting from reactive to proactive strategies. Traditional maintenance approaches often result in unplanned downtime, escalating costs, and decreased productivity. Artificial intelligence (AI) is a transformative force that redefines predictive maintenance and makes operations more efficient and reliable.

How AI Drives Predictive Maintenance

- Data Collection and Analysis: AI systems excel at gathering and analyzing extensive data from diverse sources, including sensors, historical records, and environmental variables. Machine learning algorithms sift through this data to uncover patterns and correlations that could signal impending equipment failures.

- Predictive Modeling: AI employs advanced machine learning techniques, such as time series analysis, regression models, and neural networks, to create predictive models. These models assess equipment health and predict potential failures with remarkable accuracy, offering a foresight that traditional methods lack.

- Real-Time Monitoring and Alerts: AI systems continuously monitor equipment performance, identifying anomalies and deviations from normal conditions. These systems generate automated alerts upon detecting potential issues, enabling maintenance teams to act swiftly and prevent unexpected downtimes.

- Optimization of Maintenance Schedules: AI helps fine-tune maintenance schedules by anticipating equipment failures. This ensures that resources are allocated efficiently and critical components receive attention before failure, optimizing the overall maintenance process.

Benefits of AI-Powered Predictive Maintenance

- Minimized Downtime: AI-driven predictive maintenance can significantly reduce unplanned downtimes by foreseeing and addressing potential failures in advance, thus enhancing operational continuity and productivity.

- Reduced Maintenance Costs: Optimized maintenance schedules and early intervention help lower maintenance expenses by reducing the need for urgent repairs and component replacements.

- Enhanced Equipment Reliability: Proactive maintenance through AI ensures higher equipment reliability by identifying and resolving issues before they escalate into significant failures.

- Improved Safety: Predicting equipment malfunctions with AI enhances safety by preventing accidents and injuries that could arise from equipment breakdowns.

- Informed Decision Making: AI-powered insights enable organizations to make data-driven decisions, improving operational efficiency, reducing costs, and enhancing customer satisfaction.

Real-World Applications of AI-Powered Predictive Maintenance

- Manufacturing: AI-driven predictive maintenance monitors machinery health in manufacturing, reducing downtime and ensuring high product quality.

- Energy Sector: Power plants use AI to forecast equipment failures, ensuring a reliable energy supply and minimizing maintenance costs.

- Transportation: AI helps monitor vehicle health, prevent breakdowns, and enhance safety across various transportation sectors.

- Healthcare: Predictive maintenance powered by AI ensures the reliability of medical devices, contributing to safer and more dependable patient care.

Enhancing IoT Security and Predictive Maintenance with Blockchain and AI

Security and efficiency are paramount in IoT networks and maintenance operations, and integrating blockchain with AI offers robust solutions. Here’s how these technologies enhance both fields:

Blockchain Solutions to IoT Security Challenges

- Data Privacy: Blockchain offers a secure, immutable ledger for storing IoT data. Incorporating encryption and smart contracts ensures that sensitive information remains protected from unauthorized access.

- Device Authentication: Each IoT device can be assigned a unique digital identity through blockchain. This identity is validated using cryptographic methods, safeguarding against unauthorized access and counterfeiting.

- Supply Chain Integrity: Blockchain provides a transparent record of an IoT device’s lifecycle, from manufacturing through distribution. This visibility helps prevent the entry of counterfeit or compromised devices into the market.

- Mitigating DDoS Attacks: By creating a decentralized network, blockchain enables IoT devices to collaborate in detecting and mitigating DDoS attacks. This collective approach helps in reducing the impact of such attacks.

Machine Learning in Predictive Maintenance

Regression ModelsRegression models predict continuous numerical values, making them crucial for predictive maintenance. They help estimate equipment’s Remaining Useful Life (RUL), assess the Degradation Rate, and forecast Maintenance Costs based on historical data.

- Popular Regression Algorithms include Linear Regression for straightforward predictions, Support Vector Regression (SVR) for handling nonlinear relationships and outliers, and Random Forest Regression, which combines multiple decision trees to improve accuracy.

Classification ModelsClassification models predict categorical outcomes, which is essential for evaluating equipment health and prioritizing maintenance. They help Classify Equipment Health into states like usual or critical, Predict Failure Modes, and Prioritize Maintenance Tasks based on the likelihood of failure.

- Key Classification Algorithms involve Logistic Regression for probability estimation, Support Vector Machines (SVM) for flexible data handling, Decision Trees for rule-based decisions, and Random Forest for improved accuracy through multiple decision trees.

Neural NetworksInspired by the human brain, neural networks excel at identifying complex patterns in large datasets. They include Recurrent Neural Networks (RNNs) for time-series data, Convolutional Neural Networks (CNNs) for image data, and Long Short-Term Memory (LSTM) Networks for long-term dependencies.

- Neural networks have benefits, including high accuracy, the ability to recognize intricate data patterns, and scalability to handle extensive and complex datasets.

Combining regression, classification models, and neural networks enables organizations to develop advanced predictive maintenance systems, optimizing equipment management, reducing downtime, and boosting operational efficiency.

AI-Driven Predictive Models for Critical Infrastructure

AI-driven predictive models are increasingly crucial for maintaining the reliability and resilience of critical infrastructure, such as power grids, transportation systems, and water networks. These models help predict failures, optimize operations, and enhance system performance by leveraging data from sensors, historical records, and external sources.

AI Techniques Used in Critical Infrastructure

Machine Learning

- Regression Models: Predict continuous values like energy usage or traffic flow.

- Classification Models: Categorize data, aiding equipment health monitoring and anomaly detection.

- Time Series Analysis: Examines data trends and patterns to forecast future conditions.

Deep Learning:

- Neural Networks: Recognize complex patterns, including visual inspections of infrastructure components.

- Convolutional Neural Networks (CNNs): Process image data for satellite imagery analysis and infrastructure monitoring applications.

- Recurrent Neural Networks (RNNs): Analyze sequential sensor data, providing insights into patterns over time.

By integrating these AI techniques, organizations can develop advanced predictive models that enhance the reliability and efficiency of critical infrastructure, ensuring a more resilient and optimized operation.

The Future of AI and Blockchain in IoT Maintenance

The future of AI and blockchain in IoT maintenance is promising:

- Trends: Emerging trends include more sophisticated AI algorithms and advanced blockchain solutions tailored for IoT networks.

- Technological Advancements: Innovations in AI and blockchain will drive further improvements in predictive maintenance.

- Potential Roadblocks: Challenges such as integration complexity and data privacy must be addressed to fully realize these technologies’ potential.

Conclusion

AI-powered predictive maintenance, augmented by blockchain technology, represents a transformative advancement in IoT networks. This integration enables organizations to achieve greater efficiency, security, and sustainability in their operations, paving the way for future innovations in maintenance practices and beyond.

FAQS

What algorithms are used in predictive maintenance?

Predictive maintenance often uses algorithms like machine learning (ML), deep learning (DL), and statistical methods. Standard techniques include decision trees, random forests, support vector machines (SVM), neural networks, and k-nearest neighbours (k-NN). Time-series forecasting models like ARIMA and LSTM are also used to predict equipment failures based on historical data.

How can AI be used in IoT?

AI in IoT analyzes data from connected devices for smarter decision-making, automation, and optimization. AI models can monitor IoT sensor data in real-time, predict maintenance needs, improve efficiency, and enhance security by detecting network anomalies or potential breaches.

What is the application of predictive maintenance?

Predictive maintenance is applied in manufacturing, energy, transportation, and healthcare industries. It helps predict equipment failure, reduce downtime, extend asset life, and minimize maintenance costs. This approach improves operational efficiency and reduces unplanned outages.

How is blockchain used in IoT?

Blockchain ensures secure, tamper-proof data sharing and transactions across devices. It enables decentralized communication, preventing single points of failure, enhancing privacy, and providing traceability. Blockchain facilitates automated processes like smart contracts in IoT ecosystems, improving trust and security.

Implementing Predictive Maintenance With Codearies

At Codearies, we harness the power of advanced AI and IoT to revolutionize how businesses approach maintenance. Our predictive maintenance solutions utilize machine learning algorithms to analyze real-time data from connected devices, identifying potential issues before they lead to costly failures. With our expertise in AI and IoT, we provide tailored, data-driven strategies that enhance operational efficiency and ensure long-term equipment reliability. Transform your maintenance approach with Codearies’ intelligent solutions today!