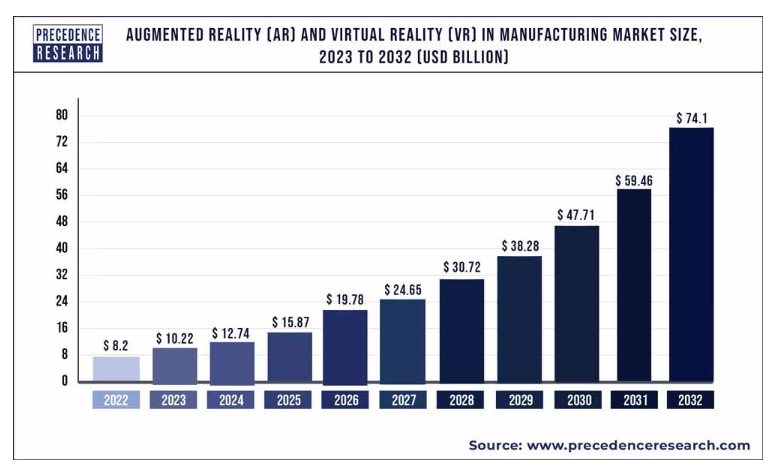

The manufacturing industry has always been a leader in adopting cutting-edge technology. With the rise of automation, increasing efficiency demands, and the push for rapid skill development, companies are continuously seeking innovative ways to train their workforce. Augmented Reality (AR) has emerged as a powerful tool in this context, providing immersive and interactive training solutions. AR-based training apps are changing the game by offering hands-on, real-time guidance, significantly improving knowledge retention and ensuring workers can perform efficiently in high-stakes environments.

What is Augmented Reality (AR)?

At its core, AR overlays digital information onto the physical world, enhancing the user’s real-world experience with virtual elements. Unlike virtual reality, which creates an entirely simulated environment, AR enriches the real world by integrating digital visuals, audio, and other sensory data. In manufacturing, AR-based training allows workers to interact with and visualize machinery and processes in real time, enhancing their understanding and proficiency with complex systems.

This integration of virtual and physical elements opens new possibilities for delivering training. Workers can follow step-by-step digital instructions overlaid on their equipment, helping them better grasp procedures, equipment operation, and safety standards.

Benefits of AR-Based Training in Manufacturing

Improved Learning Outcomes

Improved Learning Outcomes

One of AR’s key advantages is its ability to enhance learning outcomes. Traditional training methods, such as manuals and lectures, are often static and less engaging. AR transforms the learning process into an interactive experience where employees learn by doing. Workers can explore machinery functions, troubleshoot, and practice in a realistic yet risk-free environment, making the transition to real-world tasks smoother and more effective.

Boosted Safety through Simulated Training

In manufacturing, safety is paramount. AR-based training apps can simulate hazardous scenarios, allowing workers to practice emergency responses and recognize risks without facing actual dangers. This reduces workplace accidents and helps employees become more confident in managing real-life situations.

Cost-Effective Training Solutions

AR-based training minimizes training costs by reducing the need for physical resources and minimizing downtime. Employees can learn new skills virtually, speeding up the learning process and reducing errors, which in turn lowers overall training expenses and accelerates productivity.

Accelerated Learning with Real-Time Guidance

AR provides real-time, step-by-step guidance, projecting instructions onto the equipment workers are handling. This immediate feedback helps correct mistakes and speed up the learning curve. Continuous, real-time assistance also leads to fewer errors, boosting operational efficiency.

Key Components of AR Training Systems

AR Hardware: Glasses, Headsets, and Mobile Devices

The hardware used for AR training varies depending on the environment and tasks. Options include smart glasses, headsets, and mobile devices. Smart glasses, for example, provide a hands-free experience ideal for machine work, while mobile devices offer greater accessibility and flexibility. The choice of hardware depends on the specific demands of the manufacturing facility.

AR Software: Platforms Driving Immersive Learning

AR software is equally important in creating engaging training experiences. These platforms often include features such as interactive 3D models, real-time data overlays, and remote support. Customizable to meet specific industry needs, AR software simplifies the training of both new hires and experienced workers handling advanced machinery.

Integration with Manufacturing Tools

To fully leverage AR in training, the technology must be integrated with the tools and machines in use. AR apps can overlay digital instructions on machinery interfaces, guiding workers through tasks. Integrating AR with IoT-enabled devices creates a training environment that closely mirrors real-world operations.

Types of AR-Based Training in Manufacturing

Onboarding New Employees

AR-based training can streamline the onboarding process by allowing new hires to familiarize themselves with machinery and workflows in a virtual environment before working on the shop floor. This reduces the time spent in training and helps employees become productive more quickly.

Skill Development and Hands-On Learning

As manufacturing evolves, continuous skill development is necessary. AR-based apps offer immersive, hands-on learning experiences that allow employees to develop new skills without risking errors that could be costly in real-life scenarios.

Safety and Compliance Training

AR can simulate safety drills and compliance training, making it easier for workers to internalize procedures in an engaging way. AR-based simulations reinforce safety measures, ensuring workers are prepared to handle any potential on-the-job risks.

Challenges in Implementing AR Training

Technical and Adoption Barriers

While AR offers significant benefits, implementing the technology comes with challenges. High costs for hardware and software can be prohibitive, and not all facilities may have the necessary infrastructure. Additionally, compatibility issues between AR systems and specific machinery can arise.

Customization for Various Manufacturing Sectors

Every manufacturing sector has unique processes and machinery, requiring AR solutions to be tailored to meet specific training needs. Developing customized AR applications can be time-consuming and expensive.

Employee Resistance and Retention

Some workers may resist transitioning from traditional training methods to AR-based systems, particularly if they are unfamiliar with the technology. Additionally, maintaining long-term retention of skills learned via AR requires ongoing support and refreshers.

How AR is Revolutionizing Workforce Training

Real-Time, Hands-Free Learning

AR is transforming training by providing workers with real-time, hands-free guidance. With AR-enabled devices, employees can follow instructions while performing tasks, improving accuracy and reducing errors.

Closing Skill Gaps with On-Demand Training

Skill gaps are a pressing issue in manufacturing, especially with the changing workforce. AR-based training apps address this by providing on-demand guidance, allowing workers to access tutorials whenever needed, ensuring they stay updated on critical skills.

Ongoing Upskilling

AR-based training apps are highly modular, enabling continuous upskilling. As technology and processes evolve, workers can continuously refine their skills using updated AR modules, ensuring the workforce remains competitive.

Future Trends in AR-Based Training for Manufacturing

Augmented Reality (AR) is set to transform the manufacturing sector by delivering immersive and interactive training solutions. Here are some emerging trends that will shape the future of AR-based training:

Seamless Hardware and Software Integration

- Wearable Technology: Lightweight AR glasses and headsets will gain popularity, offering a hands-free training environment that enhances user comfort.

- Cutting-edge Software: Future AR platforms will feature advanced capabilities, including real-time simulations, personalized learning pathways, and deep integration with existing manufacturing systems.

AI-Driven Learning Experiences

- Customized Training: AI will analyze individual performance metrics, allowing for personalized content that adapts to each trainee’s learning pace and style.

- Virtual Mentorship: AI-powered virtual instructors will offer immediate feedback and guidance, mimicking the support traditionally provided by human trainers.

High-Fidelity Immersive Simulations

- Haptic Technology: Incorporating haptic feedback will create a more tactile training experience, helping trainees feel realistic sensations during simulations.

- Lifelike Environments: Enhanced graphics will deliver immersive training scenarios that accurately reflect real-world manufacturing environments, promoting better retention and understanding.

Integration with IoT and Digital Twins

- Live Data Utilization: AR training programs will connect with IoT devices to offer real-time insights on equipment and operational metrics, enriching the learning experience.

- Digital Twin Applications: Training on digital replicas of manufacturing systems will allow trainees to practice complex tasks in a risk-free setting, fostering confidence and competence.

Collaborative Training Environments

- Remote Expertise Sharing: AR will facilitate remote collaborations, enabling trainees to connect with experts regardless of location, thereby enhancing knowledge exchange and problem-solving.

- Team-Based Training Simulations: Collaborative exercises in AR can simulate real-world scenarios, promoting teamwork and communication skills essential in manufacturing.

Emphasis on Safety and Regulatory Compliance

- Hazard Awareness Training: AR can simulate potential hazards, allowing trainees to practice emergency responses and safety protocols in a controlled environment.

- Regulatory Compliance Education: Interactive AR content will ensure trainees understand and adhere to industry standards and regulations, making compliance training engaging and effective.

As AR technology evolves, its potential in manufacturing training will only grow, enabling organizations to elevate employee skills, enhance safety measures, and boost operational efficiency. By embracing these trends, manufacturers can create a future-ready workforce equipped for the challenges ahead.

Conclusion

As manufacturing becomes increasingly automated and complex, effective training methods are essential. AR-based training offers immersive, practical learning that enhances safety, efficiency, and engagement. Despite some challenges, the long-term benefits of AR in workforce training make it a game-changer in the manufacturing industry, positioning AR as a vital tool for the future.

FAQs

How is Augmented Reality (AR) changing the training industry?

AR is transforming training by offering immersive, interactive learning experiences. It overlays digital content onto the real world, allowing users to practice tasks in real-time, improving retention and reducing errors. AR is especially impactful in industries like manufacturing and healthcare, where hands-on training is crucial.

What is the industrial application of AR?

AR is used in industries for maintenance, assembly, and worker training. It provides real-time instructions, enhances safety, and reduces errors. Industries like automotive and aerospace use AR to guide workers and offer remote support, improving efficiency and minimizing downtime.

How is Virtual Reality (VR) used in manufacturing?

VR is used in manufacturing for training, product design, and process simulation. It allows workers to practice tasks in a virtual space, reducing risks and costs. VR also helps in designing and optimizing factory layouts, improving workflow efficiency.

What is AR in the IT industry?

In IT, AR improves user experiences and technical processes by overlaying digital content onto real-world interfaces. It is used for troubleshooting, remote support, and visualizing data, enhancing efficiency and innovation in software development and IT operations.